The Basic Principles Of machining

Exact inside of a sentence? These directions were not also exact, I obtained missing two times on my way. Perfectionists live in a specific daily life.

The rake experience which directs the flow of newly fashioned chip, is oriented at a certain angle is known as the rake angle "α". It is calculated relative on the aircraft perpendicular to your function surface area. The rake angle can be good or negative.

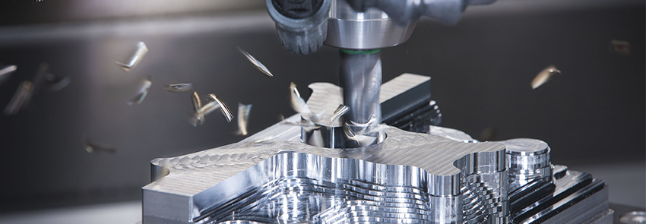

industrial processes of metalworking by chip elimination; performed by cutters on metalcutting device instruments to impart the needed shape, dimensions, and surface complete to steel sections.

precision machining Fundamentals Explained

CNC machining is without doubt one of the speediest means to develop useful prototypes, solution molds, minimal to significant volume output operates, and fixtures.

This system is employed for the creation and modification of home furnishings, shoe lasts, brush handles, boats, golfing clubs plus much more. CNC grinding, However, makes use of a disc, belt or abrasive wheel to deliver automated precision materials elimination and floor complete. CNC reducing features a broader array of tool choices, Even though the finished merchandise is none the significantly less precise. A cutting equipment may well make use of laser, h2o jet, knife, flame or plasma approaches relying upon the pros and cons they offer in particular purposes.

or in plural 2a : a living organism or among its practical programs b : one which resembles a machine (as in becoming methodical, tireless, or constantly successful) a gifted publicist and quotation machine— John Lancaster c(1) : a mix of folks acting collectively for a standard finish along with the businesses they use creating a strong war equipment (two) : a remarkably structured political team underneath the Management of the manager or small clique a politician who challenged the nearby celebration device three : a literary system or contrivance released for dramatic influence device

That is my 2nd year of using equipment shop and I have the option to pick from a established number of pre-produced blueprints or make my very own for something I intend to make. Is there a program I can use to produce a blueprint or even a video displaying how to build them by hand? Thanks in Sophisticated!

Because getting a specific machining Middle, NIST has professional unacceptable usinagem de precisão device behavior through area electricity events which have ruined in-method sections.

5 Simple Statements About precision machining Explained

Many years of business knowledge has enabled us to supply the best high-quality milling machining products and services available to our consumers.

These are typically all machining operations. Components using a decreased machinability induce considerably less Device don, involve fewer reducing power and power, provide a better area end, and supply greater chip disposal.

Machining functions commonly divide into two classes, distinguished by intent and reducing ailments:

A 3rd form also exists, a lighter equipment, termed a mill-drill, that is a close relative of the vertical mill and really popular with hobbyists. A mill-drill is comparable in essential configuration to a little drill push, but equipped with an X-Y desk. In addition they ordinarily use far more potent motors than the usual comparably sized drill press, with potentiometer-managed velocity and customarily have extra heavy-responsibility spindle bearings than the usual drill push to handle the lateral loading around the spindle that is certainly created by a milling Procedure. A mill drill also generally raises and lowers the whole head, including motor, typically on the dovetailed vertical, exactly where a drill push motor stays stationary, even though the arbor raises and lowers inside of a driving collar. Other dissimilarities that individual a mill-drill from a drill push could be a high-quality tuning adjustment for your Z-axis, a far more precise depth halt, the aptitude to lock the X, Y or Z axis, and sometimes a method of tilting The pinnacle or the whole vertical column and powerhead assembly to permit angled slicing.

precision machining Secrets

The choice in between vertical and horizontal spindle orientation in milling device layout ordinarily hinges on The form and sizing of the workpiece and the quantity of sides in the workpiece that involve machining. Do the job where the spindle's axial movement is usual to 1 airplane, having an endmill since the cutter, lends itself into a vertical mill, where by the operator can stand ahead of the equipment and have quick access on the chopping motion by wanting down on it.